Propeller shaft bearings are crucial components in both marine vessels and industrial machinery, enabling smooth rotation, load support, and reliable power transmission. Whether in ships, trucks, or heavy equipment, these bearings ensure operational efficiency and reduce wear on critical components. In this guide, we cover everything you need to know about propeller shaft bearings, from function and operation to installation, maintenance, and future trends.

What is a Propeller Shaft Bearing and What is Its Function?

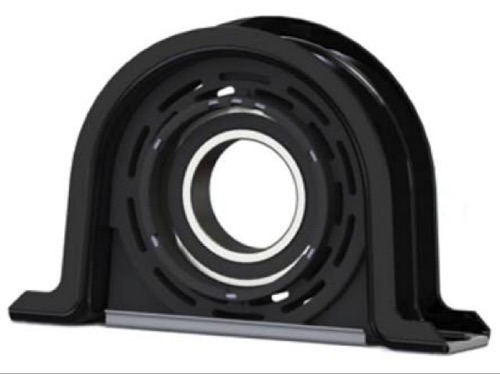

A propeller shaft bearing is a mechanical component that supports the rotation of a propeller shaft, reducing friction while managing both radial and axial loads. In marine vessels, it ensures the smooth rotation of the propeller and minimizes vibration, noise, and shaft wear. In industrial applications, it stabilizes rotating equipment such as drive shafts, turbines, and conveyor systems. Its main functions include:

- Supporting the weight and torque of the rotating shaft

- Reducing friction between moving parts

- Maintaining precise shaft alignment

- Enhancing operational safety and efficiency

Properly functioning bearings prevent premature wear and improve the longevity of the propeller shaft system.

How a Propeller Shaft Bearing Works and Sizes

Propeller shaft bearings allow the shaft to rotate smoothly while withstanding heavy loads. Rolling elements such as balls or rollers inside the bearing reduce friction and distribute forces evenly across the shaft. Sealed or shielded designs protect the bearing from dust, moisture, and contaminants, which is essential in harsh marine and industrial environments.

Common Sizes

Propeller shaft bearings come in a variety of standard and custom sizes to suit different applications:

22mm, 25mm, 28mm, 30mm, 32mm, 35mm, 38mm, 40mm, 45mm, 50mm, 55mm, 60mm, 65mm, 70mm, 75mm, 80mm, and larger sizes for heavy-duty shafts.

Types of Propeller Shaft Bearings

Depending on the application and operating conditions, several types of propeller shaft bearings are used:

- Ball Bearings: Ideal for high-speed shafts with lower load requirements

- Roller Bearings: Suitable for heavy radial and axial loads in trucks and industrial machinery

- Spherical Roller Bearings: Handle misalignment and high load conditions in marine applications

- Composite Bearings: Lightweight, corrosion-resistant solutions for specialized environments

- Self-Aligning Bearings: Automatically compensate for shaft misalignment, improving lifespan

Selecting the correct type is essential for durability and smooth operation.

Choosing the Right Propeller Shaft Bearing

To select the right propeller shaft bearing, consider:

- Load capacity and torque requirements

- Shaft diameter and operating speed

- Environmental exposure (saltwater, dust, chemicals)

- Temperature range

- Maintenance and lubrication requirements

- Alignment tolerances

- Noise and vibration levels

Marine applications require corrosion-resistant or stainless-steel bearings, while industrial drives often prioritize load capacity and thermal resistance.

Installation Best Practices

Proper installation is critical for performance and longevity. Best practices include:

- Ensuring accurate shaft alignment

- Using correct press-fit or mounting techniques

- Applying recommended lubricants

- Keeping the bearing and surrounding area clean

- Checking run-out and clearance

- Following manufacturer guidelines

Incorrect installation can lead to premature failure and costly repairs.

Routine Maintenance for Longevity

Regular maintenance ensures reliable performance:

- Inspect seals and lubrication levels regularly

- Check for unusual noise, vibration, or heat

- Clean surrounding areas to prevent contamination

- Replace worn or damaged bearings promptly

- Monitor operational conditions and loads

Well-maintained bearings can last years even under demanding marine or industrial conditions.

Troubleshooting Common Issues

Common issues with propeller shaft bearings include:

- Excessive vibration → often caused by misalignment

- Overheating → due to inadequate lubrication

- Noise → indicating wear or contamination

- Shaft scoring → caused by dirt or improper fit

- Seal damage → leading to lubricant leakage

Timely troubleshooting helps prevent serious shaft or drivetrain damage.

Challenges and Future Trends - 2026 Outlook

Current Challenges:

- Increasing load demands in industrial and marine applications

- Continuous operation under harsh conditions

- Exposure to corrosion, dust, and chemicals

- Tight maintenance schedules

Future Trends:

- Smart bearings with temperature, vibration, and lubrication monitoring

- Advanced coatings for corrosion and wear resistance

- Lightweight, high-strength materials for efficiency

- Self-lubricating and low-maintenance designs

- Integration with automated and electric propulsion systems

Contact Balaji Bearing India to Buy Propeller Shaft Bearings:

Email:balajibearingco.16@gmail.com

Website:https://balajibearingindia.in/

You can reach out directly to inquire or request a quote for Propeller Shaft Bearing.

Balaji Bearing Co.

Balaji Bearing Co.